ในตลาดออพติคอลระดับไฮเอนด์ เส้นทางทางเทคนิคที่เลือกไว้ เลนส์โฟโตโครมิก กำหนดประสบการณ์การมองเห็นของผู้ใช้และความทนทานในระยะยาวของแว่นตาโดยตรง ปัจจุบัน ผู...

READ MORE

Product Series

สินค้า

-

เลนส์วิชันซิสเต็ม 1.499 UC/HC/HMC

เลนส์ 1.499 เบากว่ากระจก มีโอกาสแตกน้อยกว่ามาก และมีคุณภาพแสงเท่ากับกระจก เลนส์เรซินมีความทนทานแล... -

1.56 เลนส์วิชั่นเดี่ยว HMC/SHMC

เลนส์สายตาชั้นเดียวมีใบสั่งยาเพียงชนิดเดียวสำหรับสายตายาว สายตาสั้น หรือสายตาเอียง แว่นสายตาและแว... -

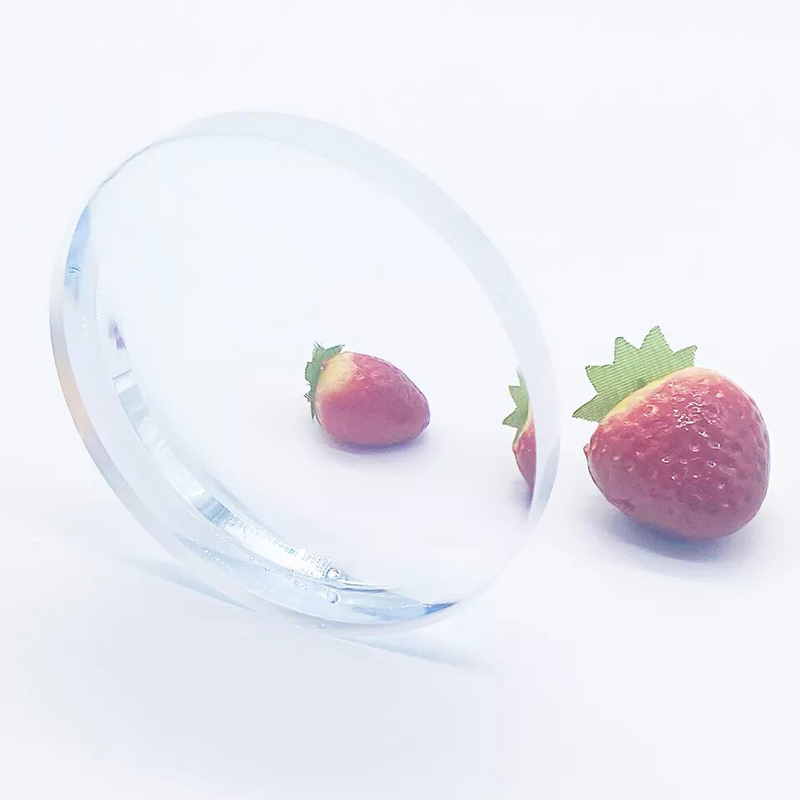

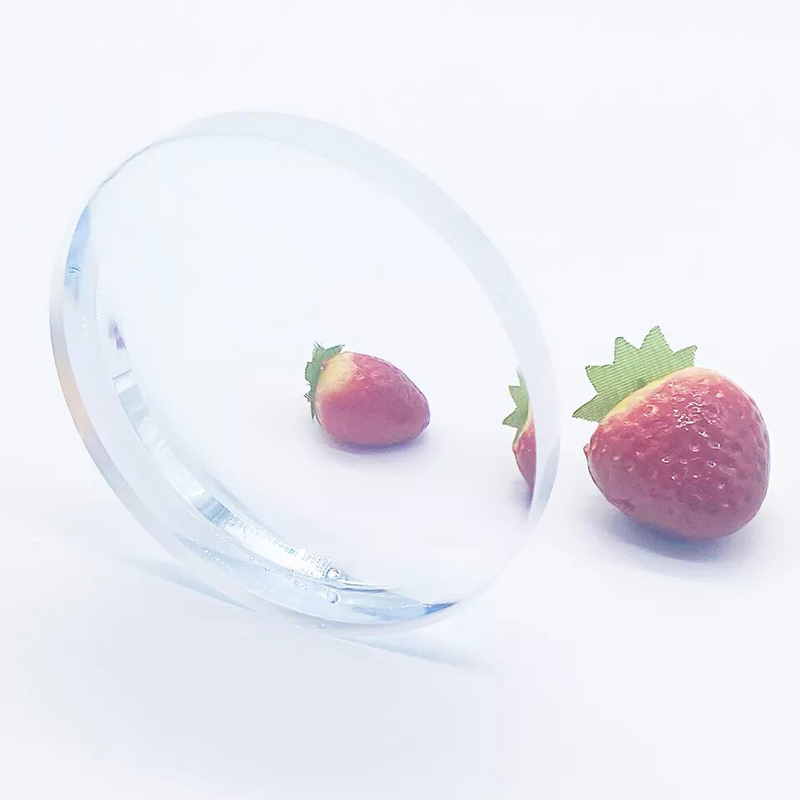

1.59 เลนส์ PC วิสัยทัศน์เดียว

เลนส์ PC เรียกอีกอย่างว่า "เลนส์อวกาศ", "เลนส์จักรวาล" ชื่อทางเคมีของมันคือโพลีคาร์บอเนตซึ่งเป็นว... -

1.60 เลนส์วิชั่นเดียว HMC/SHMC

เลนส์ดัชนี Super Thin 1.6 สามารถเพิ่มรูปลักษณ์ได้สูงสุดถึง 20% เมื่อเปรียบเทียบกับเลนส์ดัชนี 1.50... -

1.67 เลนส์ชั้นเดียว HMC/SHMC

เลนส์ดัชนีสูง 1.67 จะเป็นเลนส์ดัชนีสูงตัวแรกที่น่าทึ่งสำหรับคนส่วนใหญ่ นอกจากนี้ นี่คือดัชนีเลนส์... -

1.74 เลนส์ชั้นเดียว SHMC

เลนส์ชั้นเดียวมีใบสั่งยาเพียงชนิดเดียวสำหรับสายตายาว สายตาสั้น หรือสายตาเอียง แว่นสายตาและแว่น... -

1.499 เลนส์ Bifocal Flat Top

เลนส์สองชั้นแบบเรียบด้านบนเป็นหนึ่งในเลนส์มัลติโฟกัสที่ง่ายที่สุดในการปรับให้เข้ากับ และเป็นหนึ่ง... -

1.499 เลนส์ Bifocal Round Top

เลนส์สองชั้นเรียกได้ว่าเป็นเลนส์เอนกประสงค์ มันมี 2 เขตการมองเห็นที่แตกต่างกันในเลนส์ที่มองเห็นได... -

1.56 เลนส์โปรเกรสซีฟ HMC

เลนส์โปรเกรสซีฟเป็นเลนส์หลายโฟกัส ซึ่งแตกต่างจากแว่นอ่านหนังสือและแว่นอ่านหนังสือแบบสองชั้นทั่วไป... -

1.56 เลนส์ Bifocal Round-Top HMC

ตามชื่อเลย เลนส์สองชั้นทรงกลมจะอยู่ด้านบนสุด เดิมทีออกแบบมาเพื่อช่วยให้ผู้สวมใส่เข้าถึงพื้นที่อ่า... -

1.56 เลนส์ Bifocal Flat-Top HMC

เมื่อบุคคลสูญเสียความสามารถในการเปลี่ยนโฟกัสของดวงตาตามธรรมชาติเนื่องจากอายุมากขึ้น คุณจำเป็นต้อง... -

1.56 เลนส์ Bifocal Photochromic Round Top HMC/SHMC

ตามชื่อบ่งบอกว่าเลนส์สองชั้นทรงกลมจะอยู่ด้านบนสุด เดิมทีออกแบบมาเพื่อช่วยให้ผู้สวมใส่เข้าถึงพื้นท...

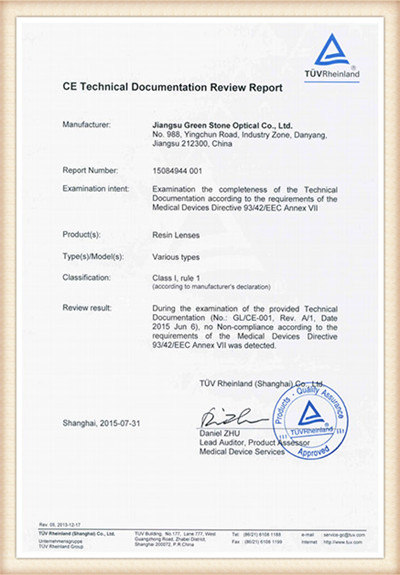

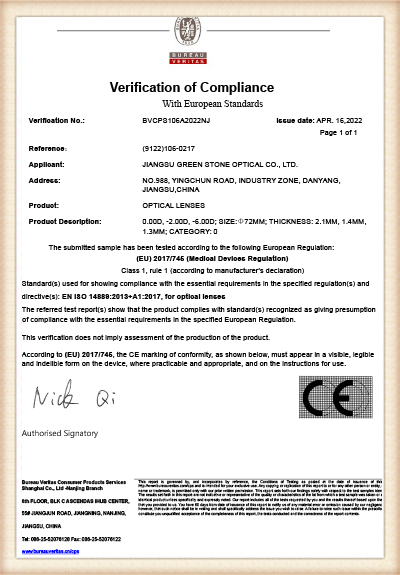

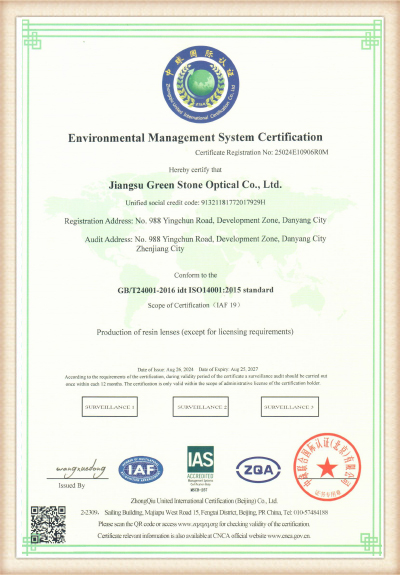

ผลิตภัณฑ์เลนส์ของเราครอบคลุมเลนส์เกือบทุกประเภท ช่วงผลิตภัณฑ์ครอบคลุมดัชนีหักเห 1.499, 1.56, 1.60, 1.67, 1.70 และ 1.74 รวมถึงเลนส์สายตาเดียว เลนส์สองชั้น เลนส์โปรเกรสซีฟ เลนส์ตัดแสงสีฟ้า เลนส์เปลี่ยนสี เลนส์ตัดแสงสีฟ้าและเปลี่ยนสี เลนส์ตัดแสงอินฟราเรด เป็นต้น พร้อมการเคลือบผิวแบบ HC, HMC และ SHMC นอกจากเลนส์สำเร็จรูปแล้ว เรายังผลิตเลนส์กึ่งสำเร็จรูปอีกด้วย ผลิตภัณฑ์ได้รับการจดทะเบียน CE และ FDA และการผลิตของเราได้รับการรับรองมาตรฐาน ISO9001 และ ISO14001

เราได้นำเทคโนโลยีการจัดการที่ยอดเยี่ยมมาใช้ และนำระบบเอกลักษณ์องค์กรมาใช้เพื่อเสริมสร้างภาพลักษณ์ภายนอกของบริษัทและแบรนด์อย่างครอบคลุม

-

-

ในด้านทัศนมาตรศาสตร์ในเด็ก การอภิปรายว่าเด็กควรสวมใส่หรือไม่ เลนส์โฟโตโครมิก มีการพัฒนาอย่างมีนัยสำคัญ ด้วยความก้าวหน้าของเทคโนโลยีด้านการมองเห็นในปี 202...

READ MORE -

The Evolution of Optical Correction: Navigating Your Lens Choices Human visual demands have undergone revolutionary changes over the past few decades. In the past, ...

READ MORE -

เลนส์มัลติโฟกัสและเลนส์โปรเกรสซีฟคืออะไร? เพื่อเห็นคุณค่าของอย่างแท้จริง เลนส์โปรเกรสซีฟ จำเป็นอย่างยิ่งที่จะต้องกำหนดตำแหน่งที่พวกเขาอยู่ในประเภทแว่น...

READ MORE -

เลนส์ชั้นเดียว: คู่มือฉบับสมบูรณ์สำหรับการแก้ไขการมองเห็น ทำความเข้าใจเกี่ยวกับเลนส์ชั้นเดียว: คำจำกัดความและหลักการพื้นฐาน ก เลนส์ชั้นเดียว เป็นเล...

READ MORE -

Deconstructing Bifocal Lenses: The Dual-Power Solution Definition and Mechanism of Bifocal Lenses Bifocal lenses are a type of lens that inco...

READ MORE -

Semi-Finished Lenses are the cornerstone of customized prescription (Rx) eyewear in the optical industry. For eyewear professionals, a deep understanding ...

READ MORE -

Introduction to Core Concepts: The Purpose of Polarized and Photochromic Lenses Advanced lens technologies are designed to enhance visual comfort and protect the ey...

READ MORE

What Are the Differences Between HMC Lenses and Ordinary HC (Hard-Coat) Lenses?

In the modern optical industry, lens surface treatment technology directly determines the durability, visual comfort, and user experience of lenses. HMC lenses , through advanced multi-layer coating technology, not only significantly enhance scratch resistance and durability but also improve optical transmittance, reduce glare, protect against blue light, and resist dirt. As a professional optical lens manufacturer integrating R&D, production, and sales, Jiangsu Green Stone Optical Co., Ltd. is committed to providing high-quality optical lenses to global customers through precise HMC technology.

1. Basic Characteristics of HC Lenses

Ordinary HC lenses, also known as hard-coated lenses, form a transparent hard coating on the lens surface through chemical or physical methods to improve scratch resistance. HC coatings mainly prevent minor scratches and wear during daily use, maintaining clear vision. For lenses with refractive indices from 1.499 to 1.74, including single vision, bifocal, and progressive lenses, the HC coating effectively extends lens lifespan, particularly for plastic and high-index lenses, where surface hardness is critical.

However, the functionality of HC coatings is primarily limited to scratch resistance, lacking comprehensive protection against optical reflection, dirt, and blue light. Therefore, in complex lighting environments, especially during long-term use of computers or mobile devices, a single HC coating cannot meet modern consumers’ multiple demands for visual comfort and protection.

2. Core Advantages of HMC Lenses

In contrast, HMC lenses apply multiple layers of coating on the lens surface, integrating hardness, anti-reflection, anti-smudge, and anti-glare functions, making them an upgraded version of HC lenses. Jiangsu Green Stone Optical Co., Ltd. ’s HMC process is suitable not only for single vision, bifocal, and progressive lenses but also for high-value lenses such as blue-cut, photochromic, blue-cut photochromic, and infrared-cut lenses.

The multi-layer structure of HMC coatings effectively reduces surface reflection, enhances optical transmittance, and provides wearers with clearer and more natural vision. Additionally, multi-layer coatings have anti-oil, water-repellent, and anti-smudge properties, reducing fingerprints, dust, and grease adhesion, and lowering maintenance effort. Especially for high-index lenses (such as 1.67, 1.70, and 1.74), HMC significantly improves surface reflectivity, enhancing aesthetics and durability.

Moreover, HMC lenses perform excellently in blocking blue light, ultraviolet, and infrared rays. By applying specific functional layers on the lens surface, HMC lenses can effectively block harmful light, reduce eye fatigue, and protect visual health. This feature is particularly valuable for office workers who spend long hours using electronic devices or for outdoor workers.

3. Detailed Comparison Between HC and HMC Lenses

| Performance Dimension | HC Hard-Coat Lenses | HMC Multi-Coating Lenses |

|---|---|---|

| Scratch Resistance | Improves surface hardness, prevents minor scratches | In addition to scratch resistance, multi-layer structure enhances wear resistance |

| Anti-Reflection | Not significant | Reduces glare, improves optical transmittance |

| Dirt Resistance | None | Oil-proof, water-proof, dust-proof |

| Blue Light Protection | None | Effectively blocks harmful blue light |

| Optical Comfort | General | Provides clear, natural vision and reduces glare |

| Applicable Lens Types | Lenses of various refractive indices | Single vision, bifocal, progressive, and high-value functional lenses |

4. Advantages of HMC Lenses from Jiangsu Green Stone Optical Co., Ltd.

With a 65,000-square-meter modern production base and over 350 professional employees , Jiangsu Green Stone Optical Co., Ltd. has introduced complete advanced equipment and new production technologies to ensure that every HMC lens has a uniform, stable, and durable coating. The company’s products cover the domestic market and are exported globally, ranging from 1.499 to 1.74 refractive index lenses, all available with HC, HMC, and SHMC multi-layer coatings. Strict ISO9001 and ISO14001 certifications ensure that each lens meets international standards for durability, optical performance, and safety.

What Are the Materials and Processes of HMC Multi-Layer Coatings?

1. Material Composition of HMC Multi-Layer Coatings

HMC lens coatings typically consist of multiple optical functional materials, precisely deposited to form stable and durable layers. Main materials include:

Hard Coat Base Layer

The first layer in HMC is usually the hard coat base, enhancing lens surface hardness to prevent scratches. Common materials include acrylic or epoxy-based optical resins, cured via photochemical or thermal processes to form a transparent, uniform hard layer.

High Refractive Anti-Reflection Layer

One core function of HMC is anti-reflection. Anti-reflection layers typically use inorganic materials such as silicon dioxide (SiO₂), titanium dioxide (TiO₂), zinc oxide (ZnO), or magnesium fluoride (MgF₂). The layer thickness is precisely controlled to reduce reflections at specific wavelengths, improving lens transmittance and reducing glare and eye fatigue.

Functional Optical Layers

Depending on lens function, HMC coatings may include blue light filters, UV blocking layers, or infrared reflecting layers. Blue light filters often use organic dyes or nanoparticles to block high-energy blue light. Infrared layers typically use indium tin oxide (ITO) or other conductive thin films to reflect infrared while maintaining high optical transmittance.

Hydrophobic/Oleophobic Top Layer

The surface of HMC lenses is usually covered with a hydrophobic and oleophobic layer, making lenses water-, oil-, and dirt-resistant. Fluoropolymer materials reduce fingerprint, dust, and water droplet adhesion, improving ease of cleaning.

2. Process Flow of HMC Multi-Layer Coatings

Lens Pre-treatment: Lenses are cleaned and dried to remove grease, dust, and impurities, ensuring adhesion and uniformity of the coating. The company uses ultrasonic cleaning combined with dust-free drying for flawless lens surfaces.

Hard Coat Base Layer Application: In automated coating equipment, the hard coat base is evenly applied to the lens surface and cured via UV or thermal processes to provide basic scratch resistance.

Multi-Layer Vacuum Coating Deposition: Using vacuum evaporation, sputtering, or magnetron sputtering, different materials are precisely deposited according to the designed thickness, forming optical interference layers. Each layer’s thickness is controlled to nanometer precision to ensure anti-reflection, transmittance, and specific wavelength blocking.

Functional and Top Layer Treatment: Depending on lens function, blue light or infrared layers are deposited, and a hydrophobic/oleophobic top layer is applied to complete the HMC lens.

Quality Inspection and Shipment: Each HMC lens undergoes testing for transmittance, reflectivity, coating thickness, and abrasion resistance. Strict ISO9001 and ISO14001 compliance ensures stable quality and meets CE and FDA standards.

3. Advantages of HMC Multi-Layer Coatings

- Scratch and wear resistance: Hard coat base combined with multi-layer coating significantly improves surface hardness.

- High optical transmittance: Multi-layer anti-reflection coatings reduce glare and improve visual clarity.

- Blue light and infrared protection: Protects vision and reduces eye fatigue.

- Dirt resistance and easy cleaning: Hydrophobic/oleophobic top layer reduces fingerprints and dirt adhesion.

- Wide applicability: Suitable for single vision, bifocal, progressive, photochromic, blue-cut, and high-index lenses.

What Are the Application Advantages of HMC Lenses in Outdoor Sports and Industrial Environments?

As modern society places increasing importance on visual health and workplace safety, high-performance optical lenses are widely used in outdoor sports and industrial environments. HMC (Hard Multi-Coating) lenses, with excellent wear resistance, anti-reflection, and multi-functional protective performance, have become a key choice in these fields.

1. Advantages in Outdoor Sports

Outdoor sports scenarios include cycling, mountaineering, skiing, golf, running, and more. These scenarios often involve intense sunlight, UV exposure, wind, and dust, posing high requirements for lens performance. HMC lenses provide the following advantages in outdoor sports:

- High transmittance and anti-glare: Multi-layer coatings reduce surface reflection and glare, enhancing optical transmittance, allowing clear and comfortable vision under strong sunlight or cloudy conditions.

- Blue light and UV protection: Effectively blocks high-energy blue light and UV rays while maintaining high transmittance, protecting eyes and reducing dryness and fatigue during exercise.

- Scratch and dirt resistance: Hard coat base combined with hydrophobic/oleophobic top layer enhances surface hardness and provides oil, water, and dirt resistance, keeping lenses clear in harsh environments.

- Compatibility with high-index and functional lenses: HMC ensures color stability and clarity under varying light conditions, suitable for single vision, bifocal, and progressive lenses.

2. Advantages in Industrial Environments

Industrial environments include construction sites, manufacturing workshops, welding sites, and outdoor operations, requiring high protection and durability from lenses. HMC lenses offer significant advantages:

- High wear and impact resistance: Hard coat base combined with multi-layer coatings improves hardness, enhancing scratch and wear resistance, extending lens lifespan.

- Anti-reflection and clear vision: Reduces surface glare and reflections, improving optical transmittance, ensuring accurate visual judgment in precision tasks, and reducing safety risks.

- Dirt resistance and easy cleaning: Hydrophobic/oleophobic top layer reduces dust, grease, and water adhesion, facilitating cleaning and maintaining long-term clear vision, improving work efficiency.

- Functional protection: Can combine blue-light filtering and infrared-blocking layers to reduce eye fatigue and potential damage, providing comprehensive protection for industrial operators.

3. Company Technological Advantages

With a 65,000-square-meter modern production base and over 350 professional technicians , Jiangsu Green Stone Optical Co., Ltd. possesses advanced coating, deposition, and thickness-monitoring equipment, combined with mature HMC processes, ensuring outstanding durability, optical performance, and multi-functional protection. Products cover lenses with refractive indices from 1.499 to 1.74, all available with HC, HMC, and SHMC coatings, certified to ISO9001 and ISO14001, CE, and FDA standards, suitable for domestic and global B2B markets.

What Are the Application Considerations of HMC Lenses with High Refractive Index Materials?

1. Characteristics and Challenges of High-Index Materials

High-index lenses are mainly made from high-index optical resins, which offer high refractive index, light weight, and thinner lens profiles, suitable for users with high prescriptions. However, high-index materials have different physical properties compared to ordinary 1.50–1.60 index materials:

- Higher brittleness, prone to scratches: High-index resins are more brittle, with slightly lower impact and scratch resistance, easily developing micro-scratches during daily wear or processing.

- Difficulty in hard coat and coating adhesion: High-index surfaces have lower surface energy, making HC or HMC coatings prone to unevenness or delamination, requiring optimized base and multi-layer coating processes.

- Significant optical interference effects: High-index lenses are sensitive to light refraction and interference, requiring higher precision in layer design and deposition thickness, otherwise color dispersion, halos, or uneven reflectivity may occur.

2. Considerations for HMC on High-Index Lenses

- Base layer design and hardening: High-index lenses require efficient hard coat base to enhance surface hardness and coating adhesion. Advanced base coating techniques with precise UV or thermal curing ensure stable adhesion for multi-layer deposition.

- Material selection for multi-layer coatings: High-index lenses require precise refractive index, layer thickness, and stacking sequence. HMC uses SiO₂, TiO₂, and other inorganic materials via vacuum evaporation or magnetron sputtering, ensuring uniform and stable coatings while maintaining anti-reflection, blue-light filtering, and dirt resistance.

- Layer thickness control and optical optimization: Each coating layer’s thickness must be precisely controlled to avoid interference, color dispersion, or glare. Jiangsu Green Stone Optical Co., Ltd. uses advanced thickness-monitoring equipment to achieve nanometer-level precision, ensuring transmittance and visual comfort.

- Hydrophobic and oleophobic top coating: High-index lens surfaces are prone to fingerprints, water, and oil residues, affecting clarity. HMC top coating provides easy cleaning and long-term clear vision while enhancing durability and user experience.

- Functional lens compatibility: High-index lenses often include progressive, multi-focal, blue-light filtering, or photochromic lenses. HMC must optimize layer design for each function, e.g., blue-light layers for high-index lenses and consistent color response for photochromic lenses.

3. Advantages of HMC High-Index Lenses

- Thin and aesthetically pleasing: High-index materials reduce lens thickness while HMC coatings maintain high transmittance and anti-reflection.

- Strong durability: Hard coat base combined with multi-layer coatings enhances wear and scratch resistance.

- Visual comfort: Multi-layer coatings reduce glare, color dispersion, and reflection, ensuring clear vision even during prolonged use.

- Multiple functions: Compatible with blue-light filtering, photochromic, and infrared-blocking functions, providing comprehensive visual protection.